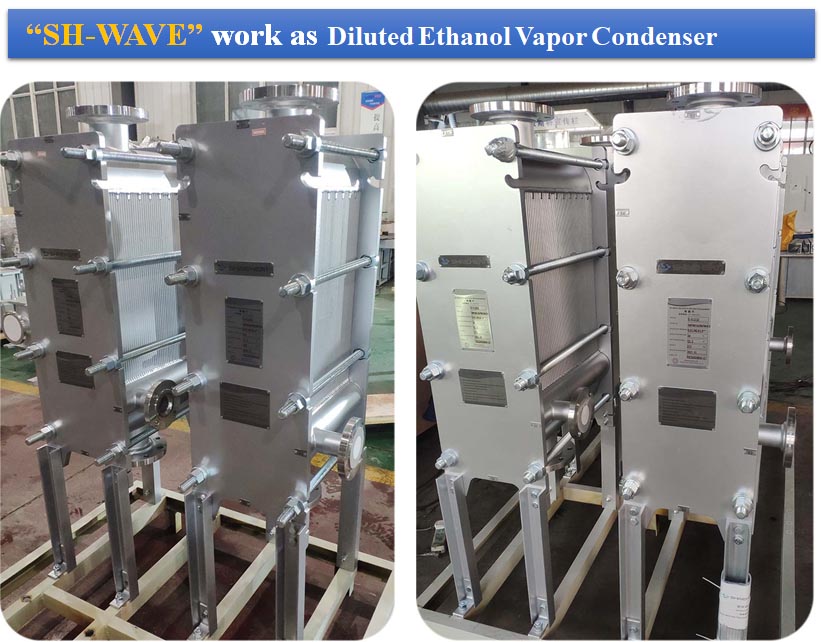

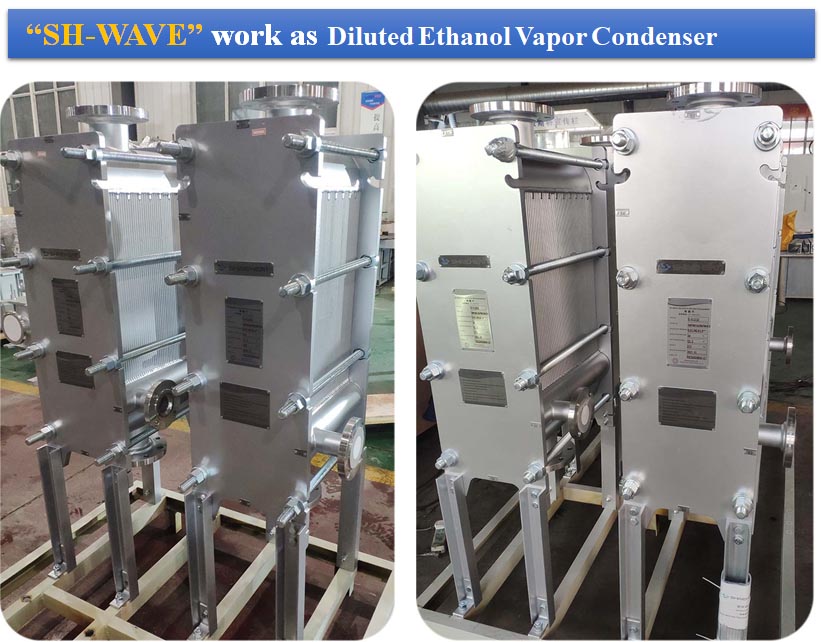

Diluted Ethanol Vapor Condenser in Chemical Plant

Original Application Data Sheet for SH Wave- Welded Plate and Frame Heat Exchanger

Original Application Data Sheet for SH Wave- Welded Plate and Frame Heat Exchanger

| |

SIDE A |

SIDE B |

| FLUID |

|

Diluted Ethanol |

Water |

| |

|

|

|

| FLOW RATE |

Kg/h |

618.0 |

30000.0 |

| INLET TEMPERATURE |

deg.C |

80.0 |

30.0 |

| OUTLET TEMPERATURE |

deg.C |

40.0 |

36.0 |

| DENSITY |

Kg/ m3 |

828/0.998 |

994.65 |

| SPECIFIC HEAT |

Kj/(kg.K) |

3.5/1.7 |

4.176 |

| THERMAL CONDUCTIVITY |

W/(m.K) |

0.19/0.02 |

0.62 |

| VISCOSITY |

cP |

0.74/0.01 |

0.752 |

| PRESSURE DROP |

KPa |

1.89 |

19.6 |

Plate Material: 0.8mm AISI 316L Plate

Frame Material: SA516

Actually, This Welded Plate and Frame Heat Exchanger is condenser for Diluted Ethanol Vapor, the inlet Diluted Ethanol is Vapor phase which contain composition gas could corrode the Rubble Gasket.

So Shineheat collect the Full Welded Plate and Frame Heat Exchanger which could avoid rubber gasket corrosion, furthermore, it could more reliable for Vapor Sealing.

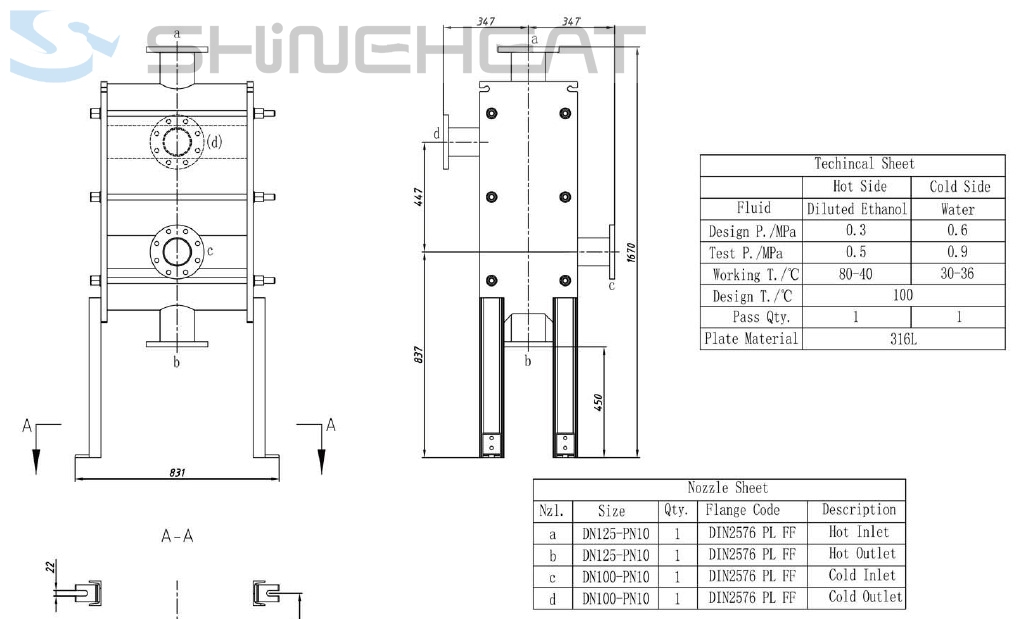

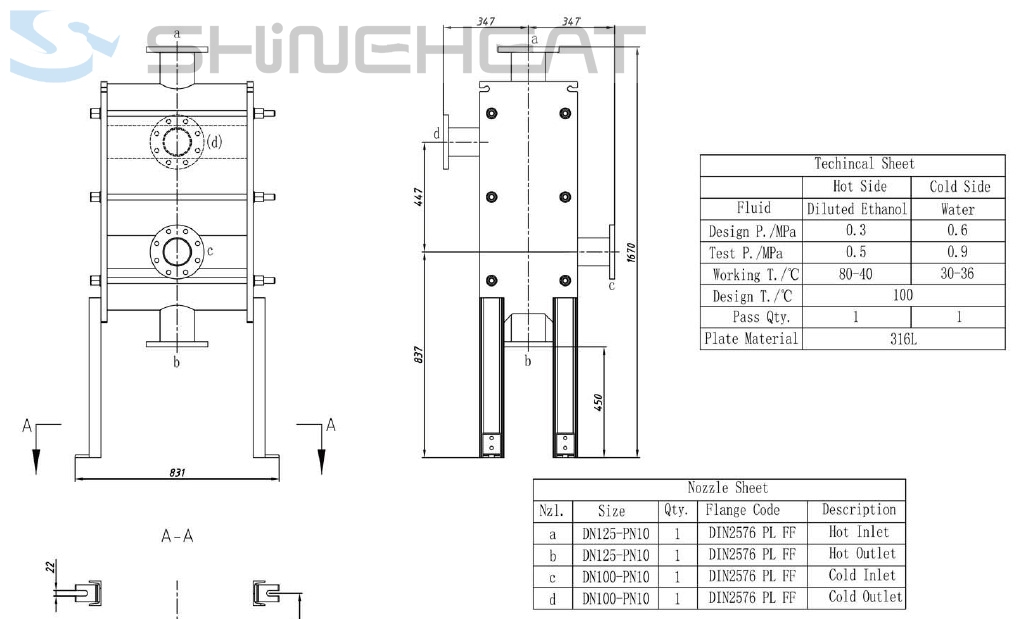

The Design Drawing for Welded Plate and Frame Heat Exchanger

At Site, new plate heat exchanger installed and operated very successfully, the delivery time is Sept 2017, up to now it is running on good condition and performance.

At Site, new plate heat exchanger installed and operated very successfully, the delivery time is Sept 2017, up to now it is running on good condition and performance.