Advanced Cooling Solution for Enriched Electrolyte in Copper Mining

SHINEHEAT TECH Plate Heat Exchanger: Advanced Cooling Solution for Enriched Electrolyte in Copper Mining

In the highly demanding environment of copper mining, where corrosive and flammable substances like enriched electrolyte are used, reliable and safe cooling solutions are essential. SHINEHEAT TECH's plate heat exchangers have been expertly designed and customized to meet the unique challenges of the Udokanskaya Med Company's copper ore processing facility. With their expertise and precision engineering, SHINEHEAT TECH has proven to be a trusted partner in the mining industry, providing innovative cooling solutions that prioritize both efficiency and safety.

The Challenge of Enriched Electrolyte Cooling

Enriched electrolyte, used in copper refining processes, is a solution that contains a high concentration of metal ions and can be both corrosive and flammable. These characteristics present significant challenges for cooling systems, which need to effectively transfer heat while preventing any potential damage or safety hazards. The cooling system must not only handle extreme temperatures but also resist corrosion and avoid the risk of leaks that could endanger workers and the environment.

SHINEHEAT TECH’s plate heat exchangers are specifically designed to meet these requirements, ensuring optimal performance even in the harshest conditions.

Special Material Selection for Durability and Safety

To address the corrosive and flammable nature of enriched electrolyte, SHINEHEAT TECH uses SMO254, a special stainless steel alloy, for all flow parts in the plate heat exchanger. SMO254 offers superior resistance to both corrosion and high temperatures, making it the ideal choice for applications involving aggressive chemicals and high thermal loads.

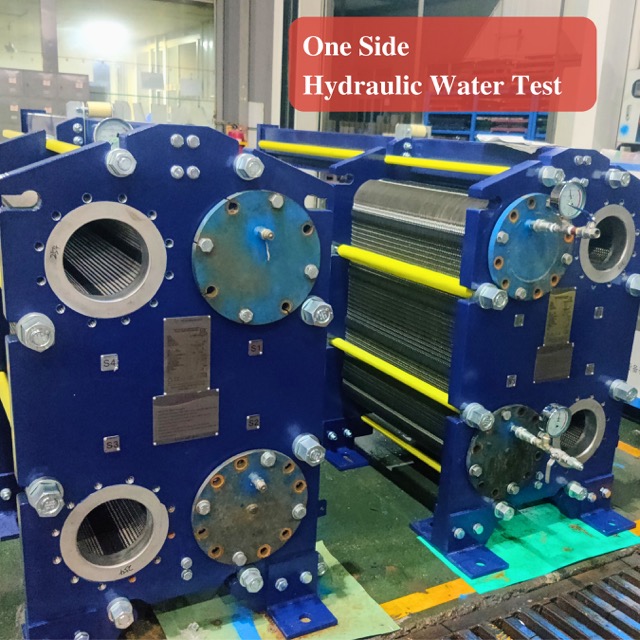

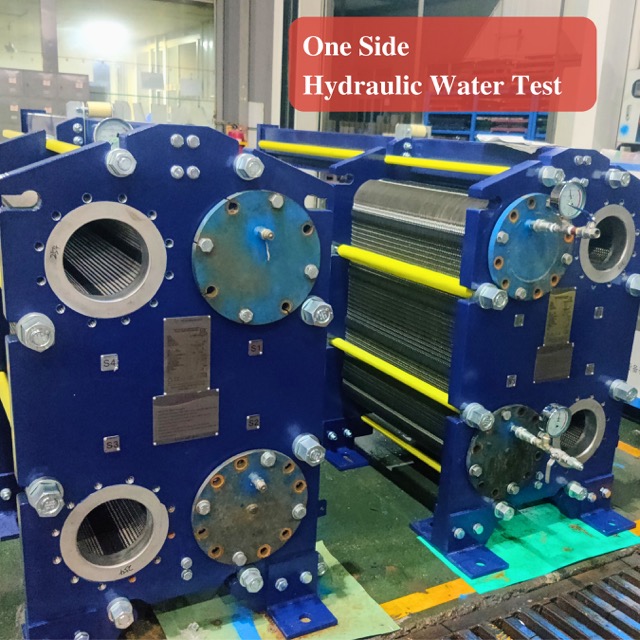

In addition to the use of SMO254, SHINEHEAT TECH employs rigorous Non-Destructive Testing (NDT) procedures to ensure the highest standards of quality and reliability. These tests include:

The Challenge of Enriched Electrolyte Cooling

Enriched electrolyte, used in copper refining processes, is a solution that contains a high concentration of metal ions and can be both corrosive and flammable. These characteristics present significant challenges for cooling systems, which need to effectively transfer heat while preventing any potential damage or safety hazards. The cooling system must not only handle extreme temperatures but also resist corrosion and avoid the risk of leaks that could endanger workers and the environment.

SHINEHEAT TECH’s plate heat exchangers are specifically designed to meet these requirements, ensuring optimal performance even in the harshest conditions.

Special Material Selection for Durability and Safety

To address the corrosive and flammable nature of enriched electrolyte, SHINEHEAT TECH uses SMO254, a special stainless steel alloy, for all flow parts in the plate heat exchanger. SMO254 offers superior resistance to both corrosion and high temperatures, making it the ideal choice for applications involving aggressive chemicals and high thermal loads.

In addition to the use of SMO254, SHINEHEAT TECH employs rigorous Non-Destructive Testing (NDT) procedures to ensure the highest standards of quality and reliability. These tests include:

- PT Testing of Plates: Ensuring there are no surface defects that could lead to leaks.

- PT Testing of Interface Bushings: Verifying the integrity of connections.

- RT Testing of Nozzles: Ensuring the strength and leak-proof quality of nozzle connections.

- Hydrostatic and Leak Testing: Conducted on both sides of the plate to ensure zero leaks.

These extensive quality control measures guarantee that SHINEHEAT TECH’s heat exchangers are not only highly efficient but also incredibly safe and reliable in challenging environments.

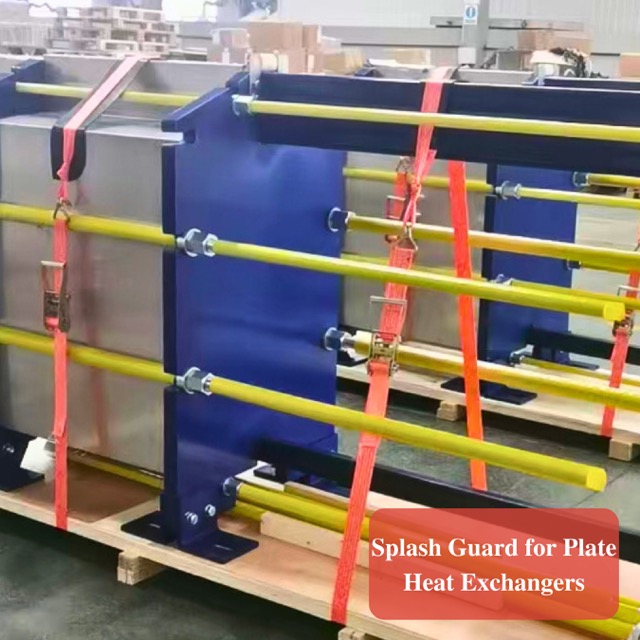

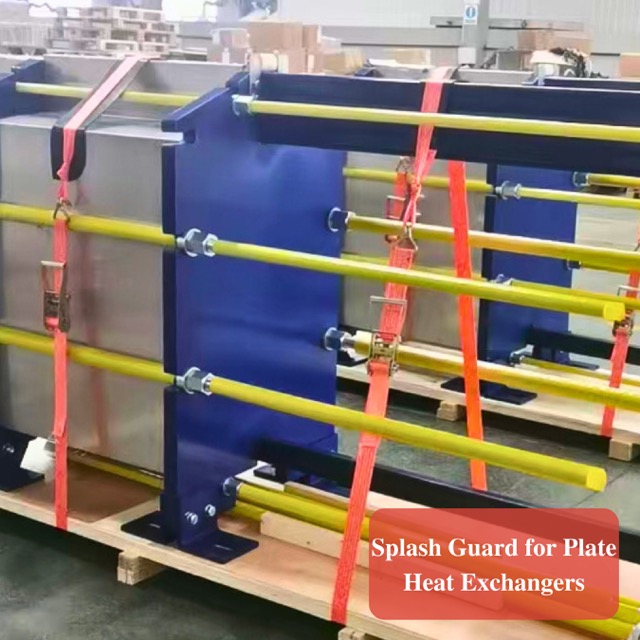

Enhanced Safety Features: Custom Stainless Steel Splash Shields

The flammability of enriched electrolyte presents a serious risk to both workers and the environment. To mitigate this risk, SHINEHEAT TECH has designed custom stainless steel 316L splash shields for the exterior of the plate assembly. These shields function like a protective armor, preventing external damage or impact from causing harm to the plate heat exchanger’s delicate structure.

In the event of a leak, the splash shields offer an additional layer of protection, ensuring that any leakage does not cause contamination, environmental damage, or fire hazards. This safety feature is particularly critical in industries like copper mining, where handling hazardous materials is a routine part of operations.

These extensive quality control measures guarantee that SHINEHEAT TECH’s heat exchangers are not only highly efficient but also incredibly safe and reliable in challenging environments.

Enhanced Safety Features: Custom Stainless Steel Splash Shields

The flammability of enriched electrolyte presents a serious risk to both workers and the environment. To mitigate this risk, SHINEHEAT TECH has designed custom stainless steel 316L splash shields for the exterior of the plate assembly. These shields function like a protective armor, preventing external damage or impact from causing harm to the plate heat exchanger’s delicate structure.

In the event of a leak, the splash shields offer an additional layer of protection, ensuring that any leakage does not cause contamination, environmental damage, or fire hazards. This safety feature is particularly critical in industries like copper mining, where handling hazardous materials is a routine part of operations.

SHINEHEAT TECH: A Trusted Partner in Copper Mining

The decision by Udokanskaya Med, the world’s third-largest copper mine, to choose SHINEHEAT TECH for their custom plate heat exchanger solution speaks volumes about the company’s expertise in the field. SHINEHEAT TECH has a proven track record in providing highly customized solutions tailored to meet the stringent requirements of industries handling aggressive substances and high-risk environments.

With its advanced materials, rigorous quality testing, and commitment to safety, SHINEHEAT TECH has solidified its position as a leading provider of plate heat exchangers, helping mining companies like Udokanskaya Med achieve optimal operational efficiency without compromising on safety.

SHINEHEAT TECH’s plate heat exchangers represent the cutting-edge of industrial cooling technology, offering a safe, efficient, and durable solution for handling the challenges posed by enriched electrolyte in copper mining operations. With their focus on quality, safety, and innovation, SHINEHEAT TECH continues to set the standard in the field, ensuring that businesses in industries like copper mining can operate with confidence and peace of mind.

SHINEHEAT TECH: A Trusted Partner in Copper Mining

The decision by Udokanskaya Med, the world’s third-largest copper mine, to choose SHINEHEAT TECH for their custom plate heat exchanger solution speaks volumes about the company’s expertise in the field. SHINEHEAT TECH has a proven track record in providing highly customized solutions tailored to meet the stringent requirements of industries handling aggressive substances and high-risk environments.

With its advanced materials, rigorous quality testing, and commitment to safety, SHINEHEAT TECH has solidified its position as a leading provider of plate heat exchangers, helping mining companies like Udokanskaya Med achieve optimal operational efficiency without compromising on safety.

SHINEHEAT TECH’s plate heat exchangers represent the cutting-edge of industrial cooling technology, offering a safe, efficient, and durable solution for handling the challenges posed by enriched electrolyte in copper mining operations. With their focus on quality, safety, and innovation, SHINEHEAT TECH continues to set the standard in the field, ensuring that businesses in industries like copper mining can operate with confidence and peace of mind.