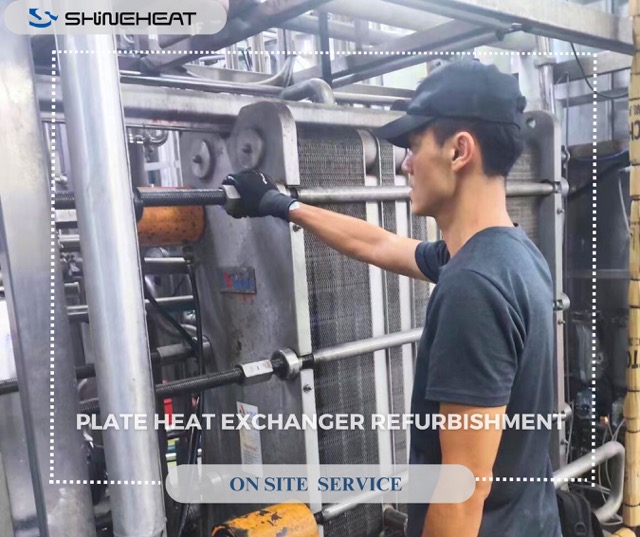

Comprehensive On-site Plate Heat Exchanger Repair and Replacement Service for APV N35 Model

Comprehensive On-site Plate Heat Exchanger Repair and Replacement Service for APV N35 Model

In the realm of industrial heat exchange solutions, the APV N35 model multi-section plate heat exchanger stands out as a reliable and robust in dairy pasteurization system. However, as with any equipment, time and usage inevitably take their toll, necessitating repairs and component replacements. Recently, a client faced this exact scenario, requiring a complete overhaul of their aged APV N35 Plate Heat Exchanger with Multi-Sections. The challenge was compounded by the lack of comprehensive technical documentation from the original manufacturer, making it difficult to provide an accurate replacement plan. This is where HESSA Tech stepped in, offering an unparalleled on-site repair and replacement service.

Understanding the Challenge

The APV N35 plate heat exchanger at the client's site had served well for many years but was now in dire need of maintenance. The critical components that required replacement were the plates and gaskets. The absence of detailed technical specifications for the N35 model's multi-section arrangement posed a significant hurdle. Without these specifications, it was impossible to determine the exact configuration and requirements for replacement parts.

HESSA’s Expert On-site Evaluation

In the realm of industrial heat exchange solutions, the APV N35 model multi-section plate heat exchanger stands out as a reliable and robust in dairy pasteurization system. However, as with any equipment, time and usage inevitably take their toll, necessitating repairs and component replacements. Recently, a client faced this exact scenario, requiring a complete overhaul of their aged APV N35 Plate Heat Exchanger with Multi-Sections. The challenge was compounded by the lack of comprehensive technical documentation from the original manufacturer, making it difficult to provide an accurate replacement plan. This is where HESSA Tech stepped in, offering an unparalleled on-site repair and replacement service.

Understanding the Challenge

The APV N35 plate heat exchanger at the client's site had served well for many years but was now in dire need of maintenance. The critical components that required replacement were the plates and gaskets. The absence of detailed technical specifications for the N35 model's multi-section arrangement posed a significant hurdle. Without these specifications, it was impossible to determine the exact configuration and requirements for replacement parts.

HESSA’s Expert On-site Evaluation

HESSA, a leading provider of plate heat exchanger services, promptly responded to the client's needs. Recognizing the complexity and importance of the task, HESSA deployed a team of highly skilled professionals from their Taiwan division. The team was tasked with on-site evaluation and manual documentation of the APV N35's multi-section plate configuration.

Detailed On-site Analysis

Upon arrival, HESSA’s experts conducted a thorough inspection of the plate heat exchanger. This included:

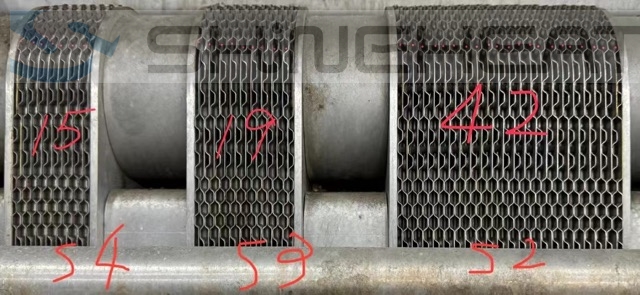

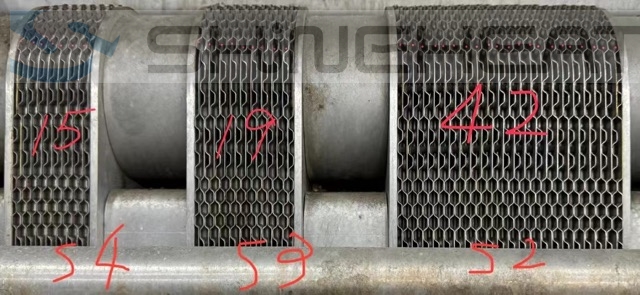

1. **Visual Inspection**: Assessing the overall condition of the exchanger and identifying any visible wear and tear.

2. **Functional Testing**: Running preliminary tests to understand the current performance and pinpoint any immediate issues.

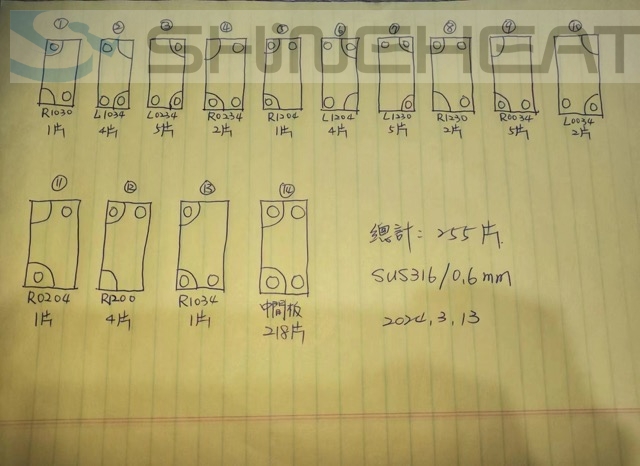

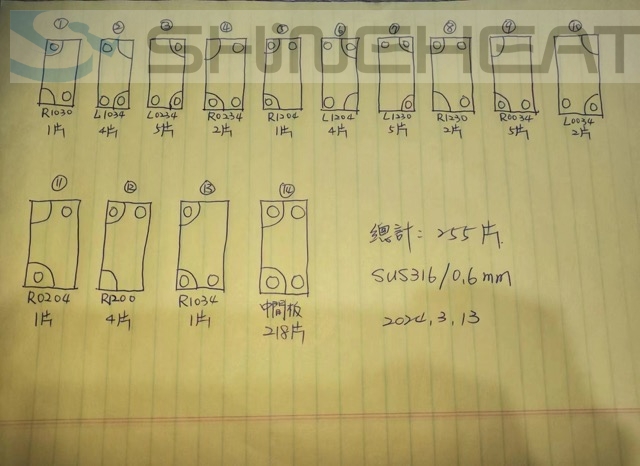

3. **Manual Documentation**: Since the original technical documents were missing, the team meticulously hand-drew the entire plate arrangement, detailing each section and its specific configuration.

HESSA, a leading provider of plate heat exchanger services, promptly responded to the client's needs. Recognizing the complexity and importance of the task, HESSA deployed a team of highly skilled professionals from their Taiwan division. The team was tasked with on-site evaluation and manual documentation of the APV N35's multi-section plate configuration.

Detailed On-site Analysis

Upon arrival, HESSA’s experts conducted a thorough inspection of the plate heat exchanger. This included:

1. **Visual Inspection**: Assessing the overall condition of the exchanger and identifying any visible wear and tear.

2. **Functional Testing**: Running preliminary tests to understand the current performance and pinpoint any immediate issues.

3. **Manual Documentation**: Since the original technical documents were missing, the team meticulously hand-drew the entire plate arrangement, detailing each section and its specific configuration.

Crafting the Replacement Plan

With the detailed drawings and on-site analysis completed, HESSA’s team could devise a comprehensive replacement plan. This plan included:

- **Exact Plate Configuration**: Using the hand-drawn schematics to ensure each replacement plate matched the original specifications.

- **Gasket Specifications**: Identifying the correct gasket sizes and materials to ensure a perfect fit and optimal performance.

Crafting the Replacement Plan

With the detailed drawings and on-site analysis completed, HESSA’s team could devise a comprehensive replacement plan. This plan included:

- **Exact Plate Configuration**: Using the hand-drawn schematics to ensure each replacement plate matched the original specifications.

- **Gasket Specifications**: Identifying the correct gasket sizes and materials to ensure a perfect fit and optimal performance.

Shineheat Tech’s Role in Component Supply

Following the creation of the replacement plan, Shineheat Tech, a trusted partner of HESSA, took charge of supplying the necessary components. Shineheat Tech specializes in manufacturing high-quality heat exchanger parts, ensuring that each component meets the rigorous standards required for industrial applications.

Supplying the Right Components

Shineheat Tech provided:

- **Custom-Fabricated Plates**: Precisely manufactured to match the exact specifications provided by HESSA’s on-site team.

- **High-Quality Gaskets**: Ensuring durability and compatibility with the APV N35 model.

Seamless Replacement and Successful Operation

With the replacement parts ready, HESSA’s team proceeded with the installation. The process was executed with precision and care, adhering to the detailed plan developed during the on-site evaluation.

Shineheat Tech’s Role in Component Supply

Following the creation of the replacement plan, Shineheat Tech, a trusted partner of HESSA, took charge of supplying the necessary components. Shineheat Tech specializes in manufacturing high-quality heat exchanger parts, ensuring that each component meets the rigorous standards required for industrial applications.

Supplying the Right Components

Shineheat Tech provided:

- **Custom-Fabricated Plates**: Precisely manufactured to match the exact specifications provided by HESSA’s on-site team.

- **High-Quality Gaskets**: Ensuring durability and compatibility with the APV N35 model.

Seamless Replacement and Successful Operation

With the replacement parts ready, HESSA’s team proceeded with the installation. The process was executed with precision and care, adhering to the detailed plan developed during the on-site evaluation.

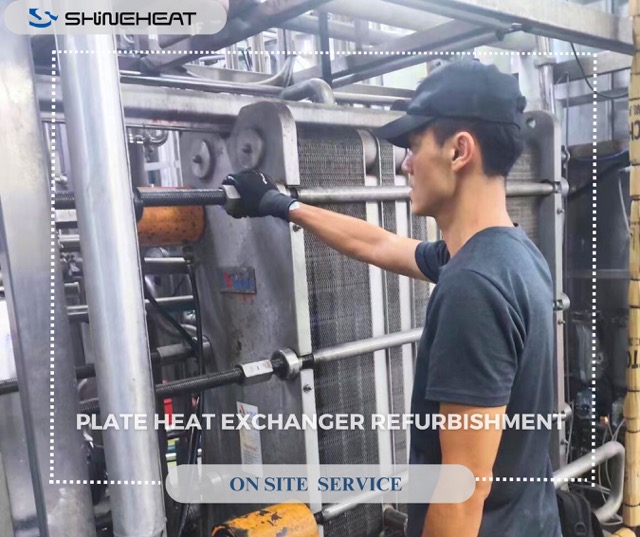

Installation Process

- **Disassembly**: Carefully dismantling the old plates and gaskets, ensuring no damage to the existing framework.

- **Cleaning**: Thoroughly cleaning the exchanger to remove any debris or buildup that could affect performance.

- **Installation**: Installing the new plates and gaskets according to the hand-drawn schematics and verified configurations.

- **Testing and Validation**: Running comprehensive tests to ensure the heat exchanger operated correctly and efficiently with the new components.

The successful repair and replacement of the APV N35 plate heat exchanger highlight the importance of expert evaluation and high-quality component supply. HESSA’s on-site service, combined with Shineheat Tech’s superior components, ensured that the client’s heat exchanger was restored to optimal functionality. This case underscores the value of professional intervention in maintaining and upgrading industrial equipment, even when original documentation is lacking.

By choosing HESSA and Shineheat Tech, businesses can ensure their heat exchange systems receive the best possible care, prolonging their lifespan and enhancing operational efficiency.

Installation Process

- **Disassembly**: Carefully dismantling the old plates and gaskets, ensuring no damage to the existing framework.

- **Cleaning**: Thoroughly cleaning the exchanger to remove any debris or buildup that could affect performance.

- **Installation**: Installing the new plates and gaskets according to the hand-drawn schematics and verified configurations.

- **Testing and Validation**: Running comprehensive tests to ensure the heat exchanger operated correctly and efficiently with the new components.

The successful repair and replacement of the APV N35 plate heat exchanger highlight the importance of expert evaluation and high-quality component supply. HESSA’s on-site service, combined with Shineheat Tech’s superior components, ensured that the client’s heat exchanger was restored to optimal functionality. This case underscores the value of professional intervention in maintaining and upgrading industrial equipment, even when original documentation is lacking.

By choosing HESSA and Shineheat Tech, businesses can ensure their heat exchange systems receive the best possible care, prolonging their lifespan and enhancing operational efficiency.