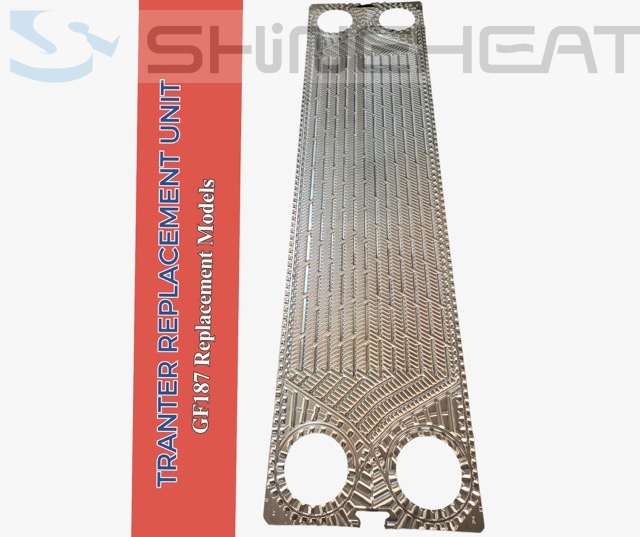

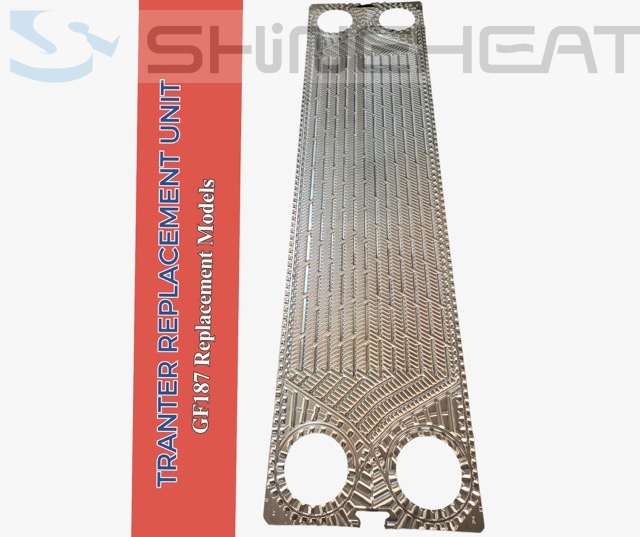

Your Superior Replacement Solution for Tranter GF187 Plate Heat Exchangers

Superior Replacement Solution for Tranter GF187 Plate Heat Exchangers

The Tranter GF187 is a prominent model within the Tranter GF series of wide-gap plate heat exchangers, specifically engineered for handling high-viscosity fluids and those containing particulate impurities. 1 Widely utilized in industries such as sugar refining, textiles, paper manufacturing, food processing, brewing, biopharmaceuticals, and waste heat recovery, the GF187's unique design features cater to demanding applications. However, its special plate patterns and deep corrugations present significant manufacturing challenges.

SHINEHEAT emerges as a reliable provider of non-OEM replacement parts and complete unit solutions for the Tranter GF187. We understand the intricacies of this model and have developed advanced manufacturing capabilities to overcome the inherent challenges.

The Tranter GF187 is a prominent model within the Tranter GF series of wide-gap plate heat exchangers, specifically engineered for handling high-viscosity fluids and those containing particulate impurities. 1 Widely utilized in industries such as sugar refining, textiles, paper manufacturing, food processing, brewing, biopharmaceuticals, and waste heat recovery, the GF187's unique design features cater to demanding applications. However, its special plate patterns and deep corrugations present significant manufacturing challenges.

SHINEHEAT emerges as a reliable provider of non-OEM replacement parts and complete unit solutions for the Tranter GF187. We understand the intricacies of this model and have developed advanced manufacturing capabilities to overcome the inherent challenges.

Challenges and Solutions in GF187 Manufacturing

Challenges and Solutions in GF187 Manufacturing

Manufacturing GF187 units requires precision and expertise due to the following factors:

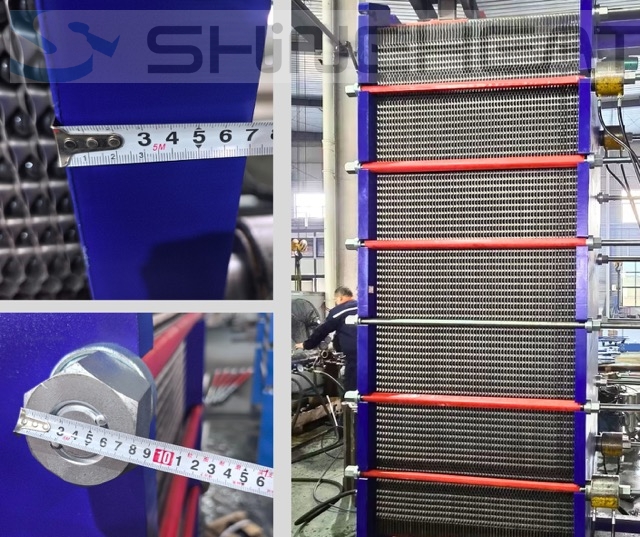

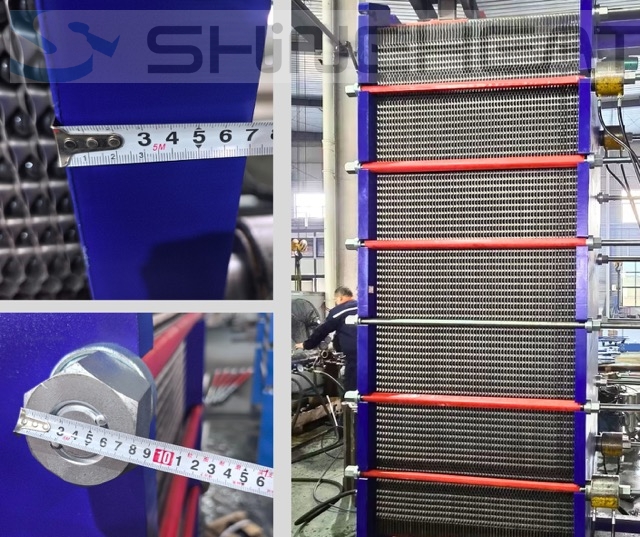

High-Capacity Pressing: The deep-corrugated plates, with thicknesses up to 8mm, necessitate the use of presses exceeding 10,000 tons. SHINEHEAT employs state-of-the-art presses capable of single-stroke forming, ensuring precise plate geometry.High-

Precision Tooling: The intricate plate patterns demand exceptionally accurate tooling. Even minor imperfections can compromise plate quality. SHINEHEAT utilizes high-precision molds to guarantee flawless plate formation.

High Pressure Testing: The wide-gap, chevron-pattern design inherently reduces pressure resistance compared to other plate types. SHINEHEAT has reinforced the frame structure by increasing frame plate thickness and employing larger, more numerous tightening bolts. This has enabled us to achieve single-side hydraulic pressure tests of 13 Barg, demonstrating our commitment to robust and reliable solutions.SHINEHEAT's GF187 Replacement Offerings

SHINEHEAT offers a comprehensive range of replacement parts and complete units for the Tranter GF187, providing customers with cost-effective and high-quality alternatives.

Replacement Plates: Manufactured to exacting standards, our replacement plates ensure seamless compatibility and optimal performance.Gaskets: We provide high-grade gaskets designed to withstand the demanding operating conditions of GF187 applications.

Complete Units: Our complete unit solutions offer a direct replacement for original Tranter GF187 exchangers, delivering equivalent or superior performance.

Why Choose SHINEHEAT?

Why Choose SHINEHEAT?

Quality Assurance: We adhere to stringent quality control measures throughout the manufacturing process, ensuring product reliability.Technical Expertise: Our team of experienced engineers possesses in-depth knowledge of GF187 technology, providing expert support and guidance.

Cost-Effectiveness: We offer competitive pricing without compromising on quality, providing exceptional value for our customers.Reliability: Our ability to perform high pressure water testing, proves that our products are very reliable.

Applications

SHINEHEAT's GF187 replacement solutions are ideal for industries requiring efficient heat transfer for challenging fluids:

Sugar Refining: Handling viscous sugar solutions and minimizing fouling.

Textile and Paper: Managing fiber-laden fluids and preventing clogging.

Food and Beverage: Ensuring hygienic and efficient heat transfer in food processing.

Biopharmaceuticals: Providing reliable heat exchange for sensitive biological solutions.

Waste Heat Recovery: Maximizing energy efficiency in industrial processes.

SHINEHEAT's commitment to quality, technical expertise, and customer satisfaction makes us the preferred choice for Tranter GF187 replacement solutions. We deliver reliable and cost-effective alternatives, ensuring optimal performance and minimizing downtime for our clients.